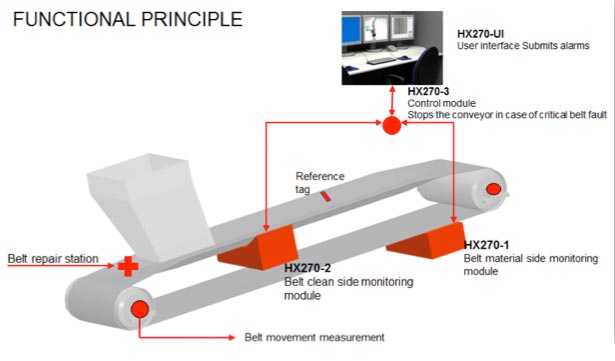

Automated on-line Conveyor Belt Monitoring and Control System

ADVANTAGES OF HX270

PROVEN SYSTEM

- Successfully in operation since around 10 years, mainly in heavy duty ore application in Scandinavia

BOTH SURFACES OF THE BELT CAN BE CONTINUOUSLY MONITORED

- Enables conveyor immediate stop when critical failure exists.

- Surface faults are detected early enough for preventive maintenance planning.

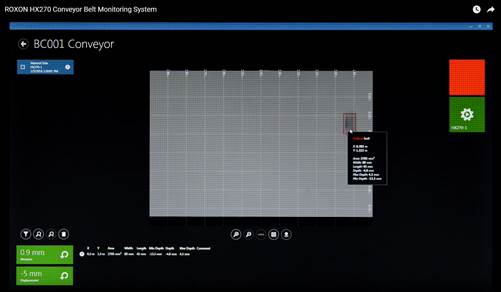

ALL BELT DAMAGE TYPES CAN BE DETECTED

- All significant belt damages in all belt types can be detected from the 3D shape of the belt surfaces

NON CONTACT OPTICAL 3D MEASUREMENT

- Wide range of textile and steel cord belt types can be monitored.

- No vulcanized wires, sensors or modifications to the belt are needed.

- Immune to color and texture changes of the belt surface.

AUTOMATIC SYSTEM

- Operator use it only when something happens to your belt, no permanent attention needed.

- Automatic drive of selected damages to maintenance station for inspection and repair.

ABRASION MEASUREMENT AND BELT MISALIGNMENT MEASUREMENT OPTIONAL

OTHER BELT MONITORING SYSTEM INTEGRATION POSSIBLE (I.E. STEEL CORD SCANNING)

CE CERTIFIED, LASER CLASS 3B